Streamline Your Operations with Barcode Labels

Mount Dora, United States - July 10, 2025 / Data Graphics, Inc. /

In today’s fast-paced business environment, every company is striving for improved efficiency. One often-overlooked solution is the implementation of barcode labels. While these might seem like simple stickers, barcode labels have the potential to transform how you manage inventory, track shipments, and automate data entry. By reducing errors and speeding up your processes, barcode labels offer significant operational advantages without requiring a complete overhaul of your existing systems.

In this article, we’ll explore how barcode labels can streamline your operations by improving accuracy, saving valuable time, and increasing overall productivity.

The Hidden Power of Barcode Labels

Barcode labels are far more than just a series of lines on a sticker. When implemented correctly, they provide a robust framework that enhances efficiency across your entire operation.

Real-Time Visibility and Tracking

A core benefit of barcode technology is real-time visibility. It allows businesses to track their inventory and orders in real time. For example, when a barcode is scanned, it instantly updates your system (such as Salesforce), providing immediate feedback on the product’s journey—from intake to delivery. This eliminates delays caused by manual data entry and ensures communication between departments is seamless.

With this real-time information, companies can proactively address issues before they escalate, ensuring that operations remain smooth and timely.

The Power of Real-Time Tracking and Data Entry

Barcode systems help reduce errors and improve operational accuracy. Traditional tracking methods, such as handwritten notes or physical logs, are prone to mistakes that can disrupt operations and lead to customer dissatisfaction. By implementing barcode systems, businesses can reduce inventory errors significantly compared to manual processes. This improvement in accuracy builds trust with clients who rely on timely, precise updates about their orders.

Barcode systems are also adaptable, making them ideal for industries with fluctuating demands, such as custom manufacturing. These systems can accommodate frequent changes without requiring extensive reconfiguration, allowing teams to pivot quickly and maintain operational flexibility.

Industry-Specific Benefits

Sectors like textile manufacturing and HVAC fabrication benefit greatly from barcode systems. These industries require precise tracking throughout various production processes. With barcode labels, each item is tracked using unique serial numbers, significantly reducing the potential for miscommunication. This clarity helps streamline internal workflows and fosters stronger relationships with customers by ensuring transparent, up-to-date information about order status.

As technology advances, it becomes clear that data management tools like barcode systems are crucial for enhancing business operations and improving overall efficiency.

Automating Data Entry with Barcodes

Traditional data entry processes are often riddled with inaccuracies, leading to wasted time and operational inefficiencies. For instance, manual entry typically has an error rate of approximately 1 in 300 characters or keystrokes, which can quickly add up when handling large volumes of data.

In contrast, barcode scanning technology boasts an error rate of just 1 in 36 trillion characters. This astonishing level of accuracy provides peace of mind and translates into significant savings in time and resources.

Method | Error Rate |

Manual Entry | 1 in 300 characters |

Barcode Scanning | 1 in 36 trillion |

This accuracy is particularly crucial in high-stakes environments like healthcare, where precise tracking of patient information directly impacts the quality of care. A simple barcode scan can automate data entry and verify its correctness almost instantaneously, ensuring that patients receive timely care without delays caused by administrative errors.

Automating data entry isn’t limited to just healthcare. Industries such as logistics and retail also benefit from barcode systems, which streamline inventory management and reduce discrepancies in stock levels.

Reducing Errors in Inventory Management

Traditional inventory management methods often rely on manual counting, which can lead to mistakes, especially in fast-paced environments. Distractions like phone calls or customer interactions can cause miscounts, leading to significant errors in inventory tracking.

When barcode labels are implemented, this chaotic scenario is transformed. Each product is assigned a unique barcode, which can be scanned to provide instant, accurate data. Employees can then count items accurately, eliminating the risk of false numbers.

Cost Implications of Inaccuracies

Even a minor miscount can lead to customer dissatisfaction or lost sales opportunities. For example, if a customer orders an item that’s out of stock due to inaccurate data, businesses could end up refunding the customer, rather than completing the sale. Barcode systems ensure high levels of inventory accuracy, improving customer satisfaction and building brand loyalty.

Enhancing Visibility and Tracking

Barcode labels are essential for providing businesses with enhanced visibility and tracking capabilities. In a world that demands speed and precision, barcode technology enables businesses to track their assets, streamline processes, and make data-driven decisions in real time.

The Real-Time Advantage

In manufacturing, barcode systems allow managers to access real-time updates on product statuses with just a single scan. This shift removes the need for cumbersome manual checks and results in an increase in operational efficiency. Workers can focus on what matters most—producing high-quality products—rather than hunting down inventory.

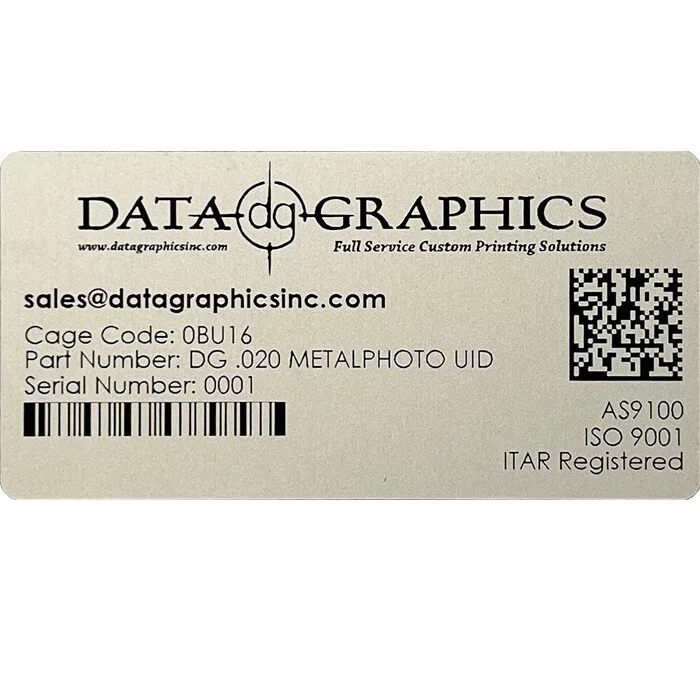

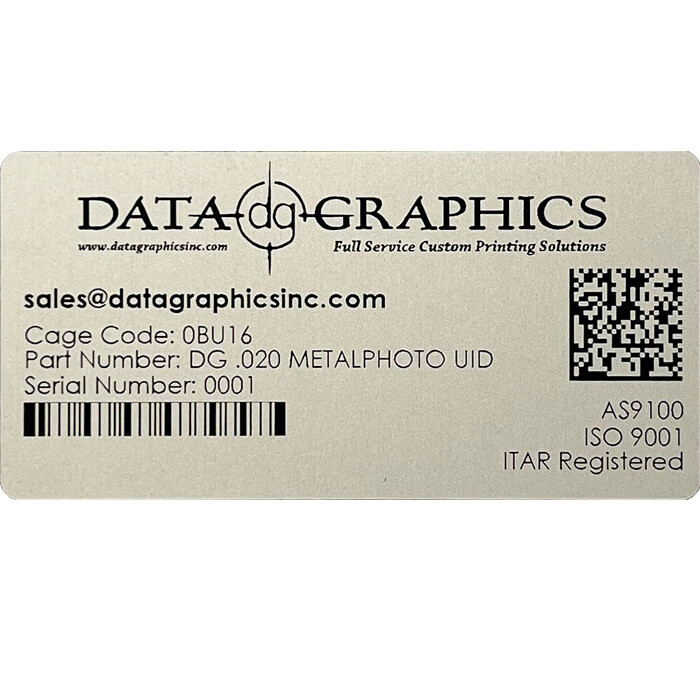

At Data Graphics Inc., we offer tailored barcode solutions designed to withstand harsh environments, such as exposure to moisture or extreme temperatures. This ensures that your visibility and tracking capabilities remain intact throughout the lifecycle of your products.

Cost Reductions and Productivity Increases

Implementing barcode labels can significantly reduce costs and boost productivity. Companies that switch from manual processes to barcode systems often see transformative results.

For example, in a warehouse setting, barcode scanning technology can reduce the time taken to locate items. This means orders are fulfilled faster, customers receive their products more quickly, and businesses experience a cycle of positive feedback and increased customer satisfaction.

Operational Efficiency Through Automation

One of the key factors in achieving operational efficiency is automation. When businesses automate inventory management with barcode technology, they reduce their reliance on human input for counting and tracking, ensuring more accurate data and fewer errors.

Barcode scanning systems integrated with inventory management software provide real-time visibility of stock levels, making it easier for staff to identify when supplies need to be reordered. This proactive approach helps businesses stay ahead of potential disruptions caused by low stock or inventory discrepancies.

At Data Graphics Inc., we offer durable, cost-effective barcode solutions that enhance productivity and ensure long-term reliability. This reduces the need for frequent replacements and helps businesses protect their investment.

Challenges and Considerations in Barcode System Implementation

While barcode systems offer substantial benefits, businesses must consider the upfront costs associated with their implementation. Investing in barcode scanners, software, and printer systems requires careful budgeting, especially for smaller companies.

Many businesses find that a phased implementation plan helps alleviate financial stress and ensures a smoother transition. This approach allows companies to integrate barcode systems gradually without disrupting daily operations.

System Integration

Integrating a barcode system with existing inventory management or enterprise resource planning (ERP) software can be complex, particularly if older systems are not compatible with new technology. However, a well-planned approach—including consultations with IT experts—can ensure a seamless integration.

Get Started with Barcode Technology Today

Incorporating a barcode system into your operations can lead to improved efficiency, reduced costs, and higher productivity. If you’re ready to streamline your operations and improve your inventory accuracy, reach out to Data Graphics Inc. today. Call us at 888.521.1143 for a free consultation and discover how custom barcode solutions can transform your business.

Contact Information:

Data Graphics, Inc.

3800 Progress Blvd

Mount Dora, FL 32757

United States

Buffy Carroll

(352) 589-1312

https://www.datagraphicsinc.com/